ULTRASONIC

VAPOR DEGREASERS

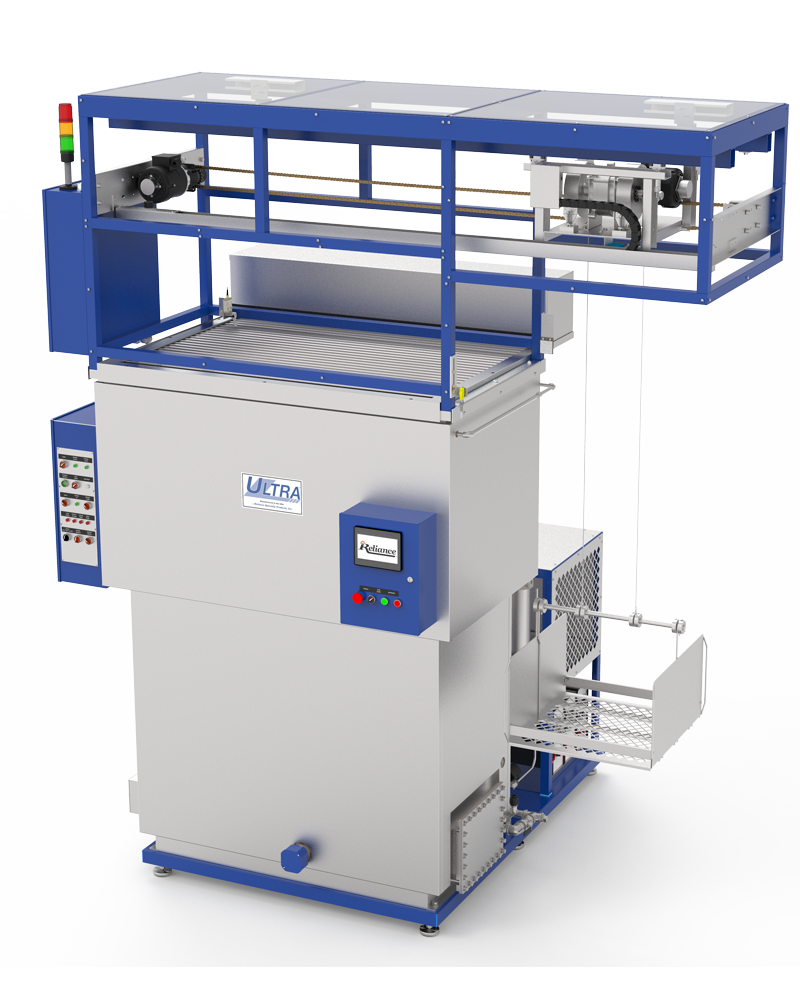

EFFICIENT CLEANING, EXCEPTIONAL PERFORMANCE: ULTRASONIC VAPOR DEGREASING

Ultrasonic vapor degreasers are an excellent option for parts that have blind holes, tight cavitation, and/or solidified contaminant. Reliance manufactures a complete line of Ultrasonic Vapor Degreasing Systems uniquely designed for:

Power, Lots of Power - Power level adjustment and frequency sweep modulation to tailor the ultrasonics for maximum efficiency in cleaning your parts

Flexibility - easy to add additional KHz

Field Maintenance Ease - Easy field replacement of basic components

Efficient Parts Processing - Ultrasonic cleaning cavitation enhances the cleaning process outperforming conventional hand scrubbing or dipping

Fast and Cost Effective Cleaning - Ultrasonics get the dirt out fast reducing cycle time and increasing throughput

All ULTRA™ units include Reliance's Standard 1 year new equipment warranty and comprehensive training.

THE FUTURE OF AUTOMATED

CRITICAL CLEANING

WHAT OUR CUSTOMERS ARE SAYING

“Production loves the existing [ULTRA] machine. Your machine cleans better than most if not all of our other machines. The Production manager is asking to acquire more of these from you. We are in the process of budgeting for next fiscal year and I believe we will get approval of at least one more machine.” ~ Mark at Varex

Ultrasonics enhance the vapor degreasing process. Ultrasonic vapor degreasing penetrates blind holes and enhances cleaning of difficult contaminants. The ULTRA™ Vapor degreasers are customizable with different wattage and sweep frequencies to ensure optimal cleaning.

OUR EXPANSIVE LINE OF EQUIPMENT

| ULTRA™ Ultrasonic Vapor Degreaser Tank Sizes | |||||

|---|---|---|---|---|---|

| ULTRA™ | MODEL | Liquid Immersion Tank (Dimensions) | Liquid Immersion Tank (Cubic Inches) |

Solvent Requirement | Automated Basket Handling System |

|

250 | 11”L x 9”W x 8”D | 792 | 5.6 gallons | |

|

1212 LE | 12”L x 12”W x 10”D | 1,872 | 17 gallons | BHE Touchscreen (35lb. Max) |

|

2012 LE | 20”L x 12”W x 12”D | 3,600 | 26 gallons | BHE Touchscreen (35 lb. max) |

|

2012-N LE | 20”L x 12”W x 12”D | 25 gallons | BHE Touchscreen (35 lb. max) | |

|

2216LE | 22”L x 16”W x 16”D | 6,688 | 56 gallons | BHS Touchscreen (100 lb. max) |

|

2424 LE | 24”L x 24”W x 24”D* *customizable depths | 13,248 | 103 gallons | BHS Touchscreen (100 lbs. max) |

| 3024 LE | 30”L x 24”W x 23”D* *customizable depths | 16,560 | 129 gallons | BHS Touchscreen (100 lbs. max) | |

| 3030 LE | 30”L x 30”W x 23”D* *customizable depths | 20,700 | 161 gallons | BHS Touchscreen (100 lbs. max) | |

|

3232 LE | 32”L x 32”W x 23”D* *customizable depths |

23,552 | 188 gallons | BHS Touchscreen (100 lbs max) |

|

3624 LE | 36”L x 24”W x 23”D* *customizable depths | 19,872 | 154 gallons | BHS Touchscreen (100 lbs max) |

| 3630 LE | 36”L x 36”W x 23”D* *customizable depths | 29,808 | 175 gallons | BHS Touchscreen (100 lbs. max) | |

|

7216 LE | 72"L x 16"W x 16"D* *customizable depths | 18,432 | 195 gallons | Gantry Hoist (300 lbs. max) |

When Should I Consider Ultrasonic Cleaning?

Ultrasonic cleaning in your vapor degreaser should strongly be considered if you have any of the following conditions or concerns:

Contaminants containing inorganic elements such as salts, metal fines, buffing compounds or the inorganic components of a flux resin) are present

Contaminants are baked on or cured or have difficulty being solubilized by your current cleaning agent, and

Parts have complex geometries, blind holes or crevices.

By introducing ultrasonics into the vapor degreasing process, the capability of the system to clean in the previously mentioned contexts is dramatically improved. At a micro level, intense activity on the surface of the parts is possible to physically displace and dislodge hard to remove insoluble contaminants as well as reach blind holes, threads and cavities that conventional solvent vapor degreaser cleaning would have difficulty reaching and cleaning. In addition, in many instances, the rate at which organic contaminants are cleaned is accelerated by the ultrasonic process.

Advantages of Automated Basket Handling Systems with Touch Screen Controls

Basket Handling Elevator BHE

Automated Basket

Handling Systems:

Minimize worker solvent exposure

Save on labor costs

Provide consistency in processing parts

BHS Lift (Horizontal &Vertical Movement)

Reliance Specialty Products, Inc.

The Only OEM Company That Manufactures Both Vapor Degreasing Equipment and Vapor Degreasing Solvent

Reliance Specialty Products, Inc. is known throughout the industry as vapor degreasing experts because we manufacture both the ULTRA™ vapor degreasing equipment line and AeroTron™ vapor degreasing solvents which are drop-in TCE and nPB replacement solvents.

ULTRA™ Vapor Degreaser FEATURES:

Minimize worker solvent exposure

Enhance solvent containment

Provide state of the art control systems

Allow easy field maintenance

Automate basket handling for consistent parts processing

Adept for the use of non-flammable solvents