BASKET HANDLING ELEVATOR (bhe) sYSTEMS

VERTICAL LIFT

Basket handling systems on vapor degreasers are becoming essential operating equipment and standard operating procedure for many companies. The ability to load parts into a basket and then have the automated system process parts while allowing the operator to perform other functions reduces cleaning processing errors while increasing productivity and efficiency. The BHE is an excellent addition to any vapor degreasing system.

NESHAP Compliant Features

Minimizes worker vapor exposure and reduces contact with the solvent.Enhanced Solvent Containment

Horizontal slide lid can be closed when parts are being processed for increased solvent containment.Labor Cost Savings

Reduces or eliminates operator processing time.Processing Consistency

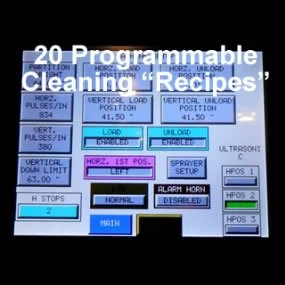

Ensures that parts are processed consistently to your specification;20 Part Cleaning Recipes

Touch-Screen PLC allows you to enter, save and easily select between 20 different part recipes.Minimized Solvent Losses

PLC controlled movement combined with sufficient time in the refrigerated flash-off zone while processing with the lid closed greatly reduces solvent losses compared to manual processing.Automated Operation

Reduces operator error and increases productivity.Process Basket with Lid Closed

Ensures solvent containment through the entire cycle.

Basket Handling Elevator Features

| Feature | Description |

| Elevator Movement | Vertical over ultrasonic immersion sump |

| Cleaning Recipe Capability | 20 recipes |

| Weight Capacity |

25 lbs. including part basket (1212 LE) 35 lbs. including part basket (2012 LE) |

| Typical Standard Basket Size |

10”L x 10”W x 4” Deep (1212 LE) 17”L x 10”W x 4” Deep (2012 LE) |

| Controller | PLC Touchscreen Controlled |

| Manual Operation Mode | Allows for manual operation of the BHE lift |

| Automated Operation Mode | Automatically processes the part basket according to the cleaning recipe selected by operator |

| Operator Selection of Cleaning Recipe | System allows for the operator selection between any of the 20 recipes that you created |

| Operator Lock-Out of Cleaning Recipe Content | Cleaning recipes are easily stored in a password-protected menu. The operator cannot change the content of a recipe. |

| Linear Movement and Positioning | Pneumatic slide with easily adjustable magnetic reed switch positioning |

| Cycle Status Light Pendant | Includes light pendant to advise of the state of the BHE lift including Ready, In Cycle, Cycle Complete and Fault Error |

| Lid Closed Basket Processing | Part baskets processed through the cleaning cycle with the lid closed for enhanced solvent containment |

Reliance Specialty Products, Inc.

The Only OEM Company That Manufactures Both Vapor Degreasing Equipment and Vapor Degreasing Solvent

Reliance Specialty Products, Inc. is known throughout the industry as vapor degreasing experts because we manufacture both the ULTRA™ vapor degreasing equipment line and AeroTron™ vapor degreasing solvents which are drop-in TCE and nPB replacement solvents.

ULTRA™ Vapor Degreaser FEATURES:

Minimize worker solvent exposure

Enhance solvent containment

Provide state of the art control systems

Allow easy field maintenance

Automate basket handling for consistent parts processing

Adept for the use of non-flammable solvents