12 Benefits of Modern Open-Top Vapor Degreasers Compared to Vacuum Vapor Degreasers

Prefer to listen along instead? Listen to the audio version below!

If you are considering a vacuum vapor degreasing system - read on…

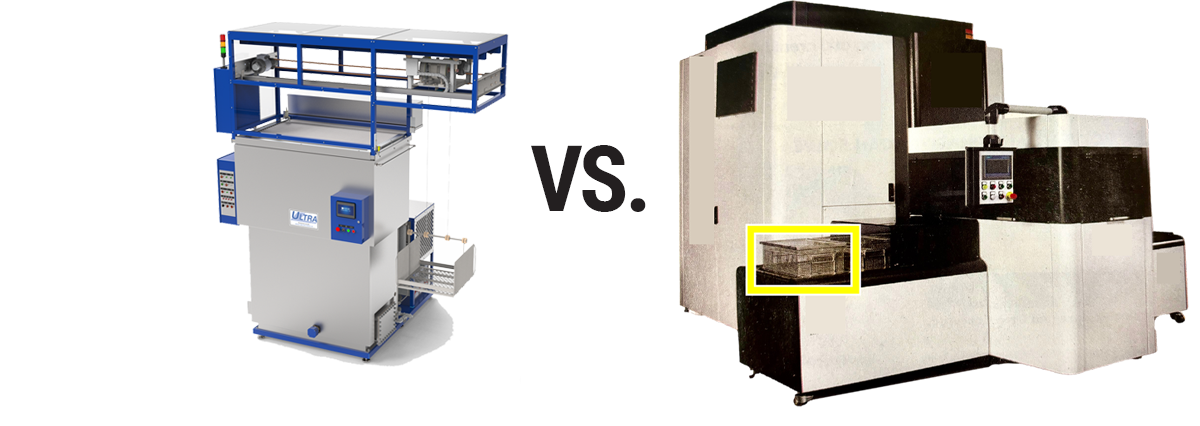

Choosing the Right Cleaning & Degreasing Technology Matters. Here we compare the benefits of Modern Open-Top Batch Vapor Degreasing Systems vs. Vacuum Vapor Degreasers

As regulatory pressures grow and environmental concerns take center stage, companies are reevaluating how they clean parts in their manufacturing operations. Solvent emissions, energy efficiency, and process control are all major factors in this decision. One of the most talked-about developments in recent years is the vacuum vapor degreaser, which promises low emissions. But how does it compare to modern open-top vapor degreasing systems?

Here, we evaluate 12 key considerations when comparing modern open-top vapor degreasing with vacuum vapor degreasing systems.

Quick Description of Modern Open-Top Vapor Degreasing System & Vacuum System

Make it stand out

Whatever it is, the way you tell your story online can make all the difference.

| Summary | What is a Modern Open-Top Vapor Degreasing System | What is a Vacuum Degreaser? |

|---|---|---|

| Brief Overview | A modern open-top vapor degreaser is a parts cleaning system that uses solvent vapor along with ultrasonic immersion to clean parts. In lieu of a vacuum for solvent containment, a modern vapor degreaser uses refrigerated coils at the top of the system to contain the solvent and minimize solvent missions and exposure. | A vacuum vapor degreaser is a parts cleaning system that extracts all of the air out of the unit and “put the system under vacuum” to seal off the tank interior as part of the cleaning cycle. Thus, in theory, operators are not exposed to solvent emissions during the cleaning cycle. The basket of parts is sealed in a vacuum chamber so solvent is not lost during processing. |

CONSIDERATIONS COMPARING BATCH VAPOR DEGREASERS to VACUUM DEGREASERS

| KEY CONSIDERATION | MODERN OPEN-TOP VAPOR DEGREASER | VACUUM DEGREASER |

| 1. INITIAL INVESTMENT COST | o Small Capital Outlay; Inexpensive | o Large Capital Outlay; Very Expensive |

| 2. LEAD TIME TO RECEIVE UNIT | o Reasonable: 14-20 weeks | o Extensive: 28-96 weeks |

| 3. CLEANING EFFECTIVENESS | o Fast, Complete Cleaning, with Consistent Repeatability | o Slow, Consistent Clean Repeatability | 4. FOOTPRINT | o Compact Space Requirement (Modular) | o Very Large/Extensive Space Required | 5. FOOTPRINT TO PROCESSING Capacity | o Minimal Footprint to Basket Size | o Very Large/Extensive Footprint to Basket Size | 6. TIME TO PROCESS BASKET | o Fast/Minutes | o Slow/Significant | 7. LABOR FOR PROCESSING | o Minimal | o Minimal | 8. DAILY OPERATION | o Simple | o Complex | 9. SOLVENT USAGE | o Based on System Size | o Requires 5-10% more due to distillation loss | 10. SOLVENT EXPOSURE | o Minimal/NESHAP Approved | o Minimal/NESHAP Approved | 11. ONGOING MAINTENANCE COST | o Simple, Staff Can Maintain | o Complex, Requires Service Contracts | 12. COMPLEXITY of MAINTENANCE | o Easy & Cost Effective | o Complicated & Expensive needing contact maintnance support |

1. Initial Cost:

Vacuum systems are complex and thus are usually twice as expensive than modern batch vapor degreasers. Vacuum systems tend to be very capital intensive upon purchase compared to a traditional vapor degreaser. A modern open-top batch vapor degreaser for the same chamber size is going to be approximately 80-100% less than the cost of a vacuum system.

2. Lead Time When Purchasing a Unit:

Vacuum systems tend to have extremely long lead times when acquiring new equipment (minimums of 7 months to a year, with delays probable). If urgency or quick turn around time is a priority, modern open-top vapor degreasers can be built new in 3 months or less, and are sometimes held in inventory or used systems can be found.

3. Cleaning Effectiveness:

Vapor degreasing is one of the most effective & efficient ways to clean parts. The solvents utilized have high Kb values and evaporate fast. Comprehensive, complete cleaning (even of blind holes & complex geometries) is a major benefit of modern open-top vapor degreasing systems - less so with vacuum systems because multi-dip processing is not available in a vacuum system which usually is a very beneficial cleaning step (especially for parts with complex geometries.) Both have automated part processing capabilities that make consistent and repeatable cleaning easily achievable.

The Footprint of a Vacuum System to Basket Size is Significant.

Very limited basket size to large vacuum unit footprint for processing

Note: Yellow box highlighting part basket

4. Actual Footprint

Because vacuum units need complex pumping systems and other mechanicals, the footprint requires more floorspace - usually twice the footprint as compared to a modern open-top vapor degreasing system. For many companies, floor space is at a premium and is expensive…adding to the overall cost of a vacuum system. Larger footprints cost money.

Modern open-top Vapor Degreasers have an economical, compact footprint usually 50% smaller than a vacuum system.

5. Footprint to Basket Size Processing Capacity:

The footprint of a vacuum system to the actual basket of parts that is being processed is enormous. A 20”x12” basket processed in a vacuum system requires 96” x 60” (40 sq. ft.) of floor space. A open-top vapor degreaser for the same basket size of 20” x 12” requires 59”L x 55”W (22 sq. ft.) of floor space. Footprint to basket size of an open-top degreaser is significantly smaller….50% smaller.

6. Basket Part Processing Time:

Processing time matters. Vacuum Systems have long part processing times because of the need to put the system under a vacuum, vaporize the solvent, then un-pressurize the system prior to releasing the basket of parts (and this would be longer based on the size of the system…adding significantly to the processing times (30-40 minutes is standard). This long process makes the vacuum unit a bottleneck in your cleaning production line. A modern open-top vapor degreasing unit can clean and dry a basket of parts in an average of 5-15 minutes (usually less if the parts have less mass) - no matter how large the batch vapor degreaser unit is! Longer cycle times cost money - and vacuum systems have long processing times with reduced overall through-put.

Video of shower head with buffing compound cleaned in ultrasonics in an ULTRA batch vapor degreasing system

7. Labor for Part Processing:

Both open-top and vacuum systems require minimal labor to complete the part processing. Once the baskets are filled and placed in the system, labor is not required to process the part basket and can be freed up for other activities. Automated processing in both the modern open-top and vacuum systems provide for consistent and repeatable part processing.

8. Daily Operation:

Between difficult maintenance, long basket processing times, and system complexity, daily operation can be jeopardized in a vacuum system. If the cleaning operation is a vital part of your production, vacuum systems might not be the best choice. Modern open-top systems are simply engineered and require minimal maintenance. Once your open-top system is in place, reliable daily operation can be expected.

9. Solvent Usage:

Many companies are enticed by the ability to use “cheaper” modified alcohols in their vacuum system. They also believe there will be reduced solvent usage because of the vacuum system. But modified alcohols come with the issue of introducing a flammable into your operation. Having flammables on site is not optimal. And the vacuum system does not ensure reduced solvent usage. A benefit of open-top vapor degreasing systems is that they have excellent solvent containment for minimal solvent usage and they utilize non-flammable solvents that leave no residue. Interestingly enough, when the solvent is distilling under vacuum, it foams - which is not ideal.

10. Solvent Exposure:

The big touted benefit of a vacuum system is that it reduces the solvent emissions and exposure to the workers. However, when doing maintenance workers are still exposed to solvent. The advanced solvents used in vapor degreasing are great hydrocarbon cleaners. Modern open-top systems have extensive refrigeration containment systems that keep solvent exposure to a minimum during and after processing. Properly maintained systems, whether open-top or vacuum, will minimize solvent exposure.

11. Ongoing Maintenance Costs:

Vacuum system are not typically maintainable by internal staff or mechanical or trade contractors, thus requiring manufacturer on-site diagnosis and repair. The sheer amount of components in a vacuum system makes ongoing maintenance expensive and time consuming. And down time could be significant waiting for parts or support from the vacuum degreaser manufacturer. Modern open-top vapor degreasing systems are easy to maintain over the long haul. The Reliance ULTRA vapor degreasers have digital read-outs and control panel monitors to help maintenance personal know quickly if maintenance is needed.

12. Complexity of Maintenance:

As noted, putting a system under vacuum requires specialized processes that are complex. Achieving a deep vacuum where the moisture and air is removed is critical to the process. This makes the system complex and difficult to service; with long lead times if something breaks. Vacuum systems are not simple to maintain. Modern open-top vapor degreasing systems are easy to maintain. The Reliance ULTRA system, uses standard, off the shelf parts easily found, purchased and installed. The simplicity and serviceability of a modern open-top vapor degreasing system provides cost economy that cannot be enjoyed with a vacuum system.

The Bottom Line: Investing in a modern open-top vapor degreasing system like the ULTRA pays for itself quickly. You’ll see up to 50% faster cleaning, lower operating and maintenance costs, reduced floor space requirements, and years of reliable, trouble-free use. When it comes to ROI, open-top vapor degreasing is the smarter choice—and makes vacuum systems look like a costly compromise.

Optimize Your Cleaning Operation with Our ULTRA Modern Open-Top Vapor Degreaser!

Engineered for efficiency and durability, our ULTRA vapor degreasers deliver powerful cleaning performance to remove grease, and machined part residue. Our ULTRA Vapor Degreasing Systems feature compact footprint, user-friendly design, adjustable temperature controls, and automation, to ensure thorough and precise cleaning while reducing operator labor.

Using advanced ultrasonic technology, the ULTRA unit delivers deep, thorough parts cleaning by emitting high-frequency sound waves that create microscopic bubbles which gently dislodge and remove dirt, grease, and contaminants from even the most intricate and delicate parts. Ideal for precision components and intricate assemblies, our ULTRA ultrasonic open-top system ensures complete cleaning of complex geometries. The ULTRA provides effortless, efficient cleaning with a device that combines power, precision, and easy maintenance.

Conclusion

Companies see the benefits of parts washing with vapor degreasing and want to continue using this effective cleaning process. And it is understandable that they want to minimize the solvent exposure and emissions to employees and the environment. So, considering a vacuum system seems to be a viable alternative. But don’t be fooled by the term “open-top” vapor degreaser. New modernized open-top degreasers are NESHAP compliant and have excellent solvent containment. Properly engineered modern closed-loop vapor degreasing system DOES minimize solvent emissions while being a very economical and efficient option. With an open-top system you can modernize your cleaning operation without breaking the bank.

As you consider a vacuum system keep in mind the significant disadvantages that negate the overall ROI:

1. Much higher system purchase cost;

2. Vacuum systems are very complex;

3. Vacuum systems are not typically maintainable by internal staff or typical mechanical or trade contractors requiring manufacturer on-site diagnosis and repair

4. Extensive downtime for repair

5. Cycle times are very long compared to a modern closed-loop vapor degreaser

6. Multi-dip processing is not available in a vacuum system and would likely be very beneficial to many types of parts (especially with tight geometries).

We have been hearing from companies that have moved into vacuum systems they feel YOYO (you are on your own) when it comes to support, transitioning from one solvent to the next and long term maintenance…and this is frustrating to say the least. Please do your homework and ask about the considerations presented - so you have the full picture for your decision making process.

_______________________________________

Give us a call or contact us to discuss your application and how the ULTRA Parts Cleaning System can support your metal fabrication operation. We can test clean parts in our lab and share our recommendations for optimized cleaning.

At Reliance, we take a comprehensive, systemic approach to supporting our customers to finding solution to their cleaning needs. Reliance Technical Support Department at 847-640-8923. We are glad to be of assistance.