CASE STUDY:

Performance Testing of AeroTron-AV-5408

Effectiveness on Various Contaminants

Introduction

Reliance Specialty Products was approached by a large Aerospace company to help validate if the AeroTron-AV-5408 solvent would effectively remove/clean a variety of contaminants (lubricants, grease, oils) that are used in their manufacturing process. The Aerospace client currently uses an nPB solvent in their vapor degreasers. As part of the validation testing to ensure meeting the cleaning specifications, the company asked Reliance to clean coupons covered in a variety of contaminants.

Reliance tested 14 different contaminants sent to us by the client:

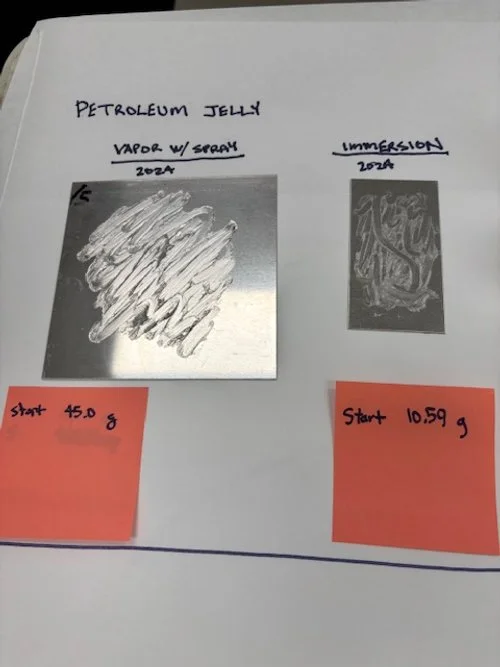

1. Petroleum Jelly Lubricant

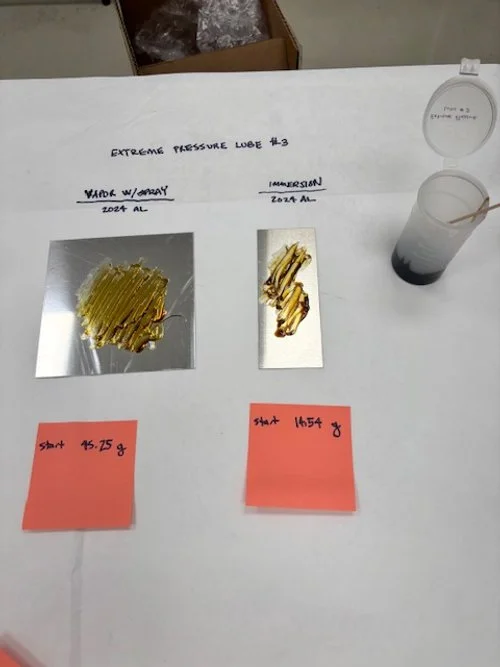

2. Extreme Pressure Lubricant #3

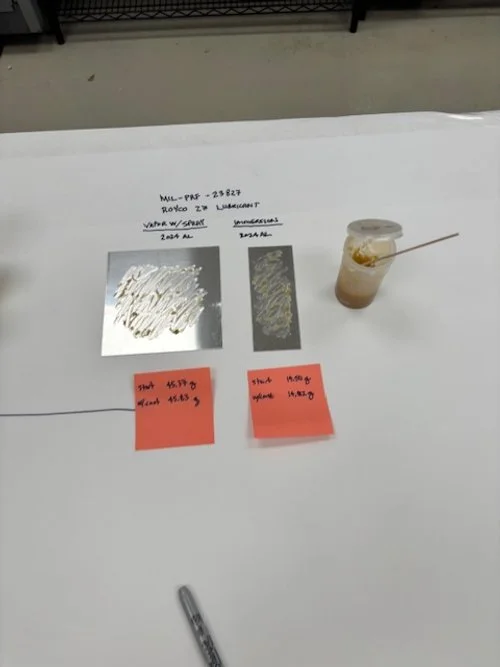

3. MIL-PFR-23827 - Royco 27 Lubricant

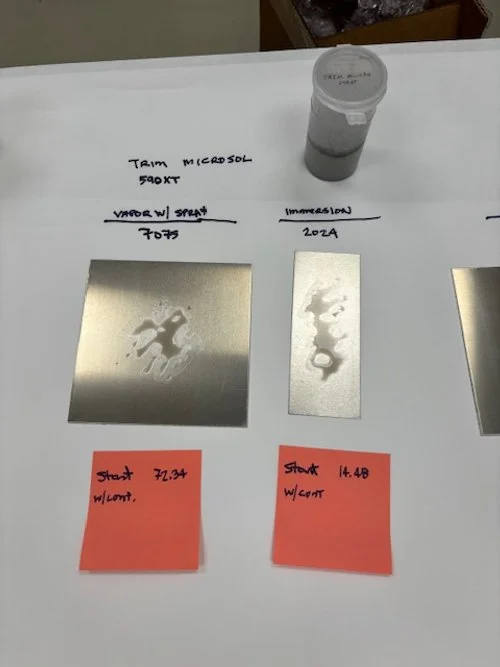

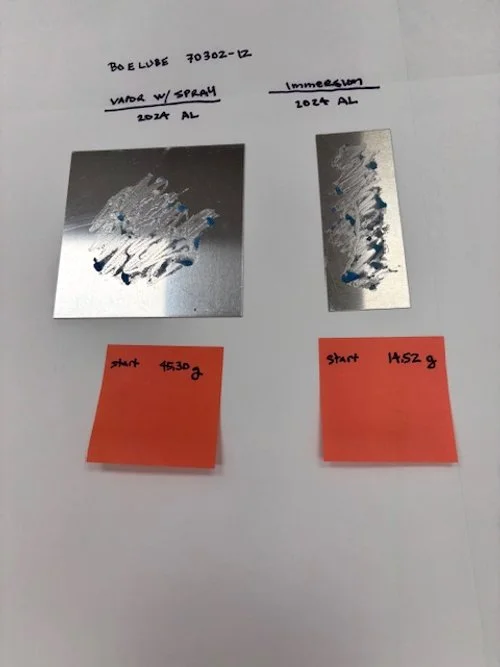

4. Boelube 70302-12 Lubricant

5. Boelube 70201-00 Lubricant

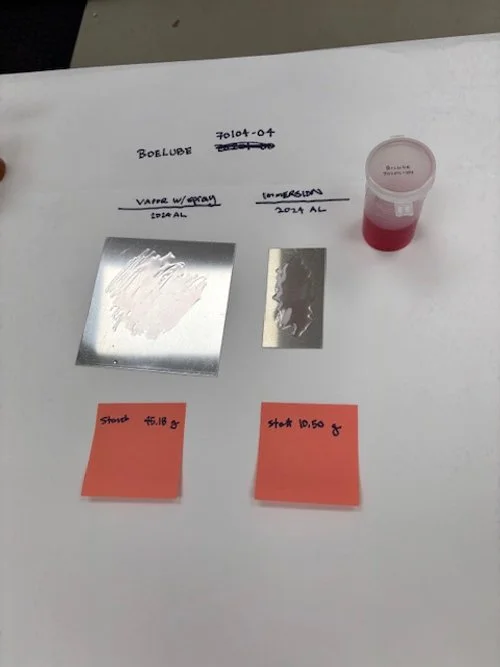

6. Boelube 70104-04 Lubricant

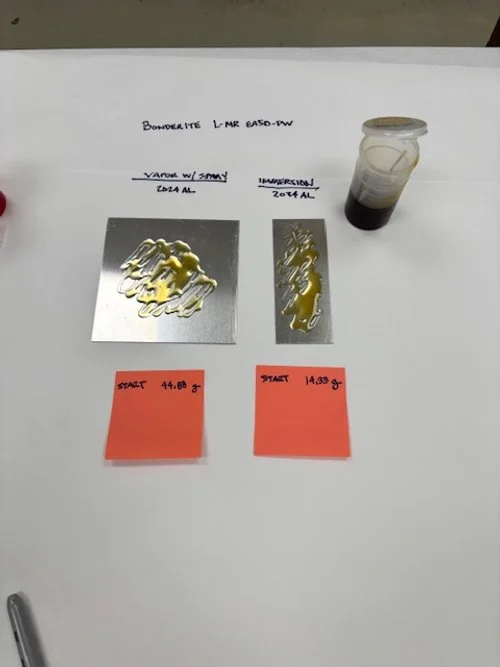

7. Bondrite L-MR- EA50-PW Aero Lubricant

8. CRC-3-36 Lubricant

9. Trim Mircosol 590XT Lubricant

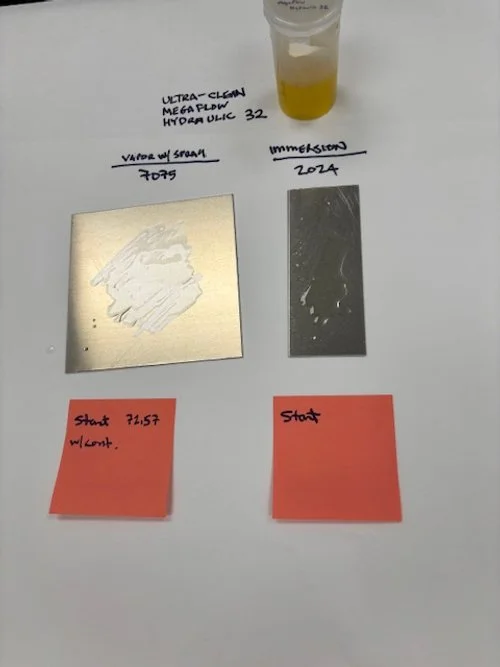

10. Ultra-Clean Megaflow Hydraulic 32

11. HC Premium Slideway 220 Lubricant

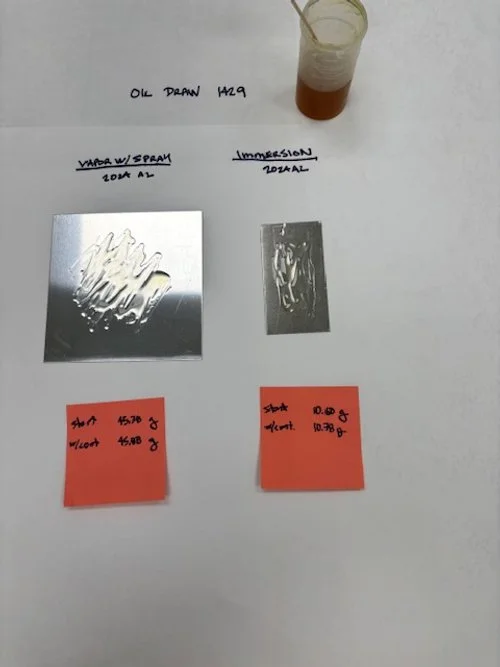

12. Oil Draw 1429 Lubricant

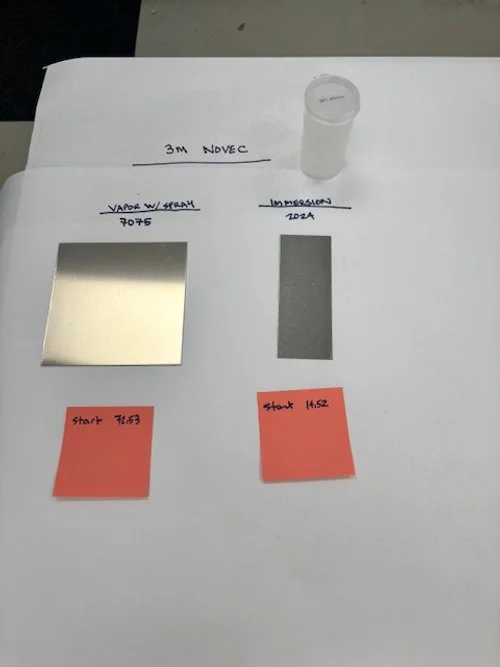

13. 3M Novec Lubricant

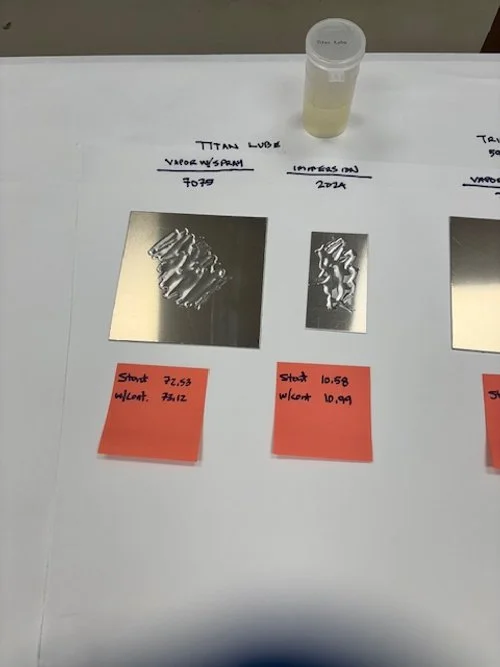

14. Titan Lube Lubricant

OBJECTIVE:

Assess the effectiveness of AeroTron-AV-5408 solvent to remove a variety of contaminants. This assessment is part of due diligence to determine if AeroTron-AV-5408 is a viable replacement for the nPB currently used in the company’s vapor degreasers.

Validation Methodology

STEP 1: As part of Reliance’s transition validation process, Reliance conducts a free initial consultation with the client company to assess what the need/problem to be addressed is, while garnering a comprehensive understanding of the current application and what the client company is interested in achieving. Once the initial consultation is completed, Reliance proposes a plan for achieving the goals and objectives, lending the expertise ad wisdom from years of vapor degreasing thousands of different kinds of parts with a multitude of contaminants.

In this case the aerospace client is interested in evaluating the effectiveness of the AeroTron-AV-5408 to replace the nPB solvent that they are currently using in their vapor degreaser.

They would like Reliance to test 14 different current contaminants and report the findings.

STEP 2: Prepare the Coupons for Testing in AeroTron-AV-5408

METAL COUPONS RECEIVED FOR PROCESSING APPLICATION OF CONTAMINANTS

We received two sets of metal coupons for applying the contaminants to test for removal of the contaminates.

1. 2024 T3 Clad Aluminum Coupon

2. 7075 T6 Bare Aluminum Coupon

SUMMARY of Coupon Preparation: 1.Coupons cleaned in vapor degreaser and wiped with IPA. 2. each coupon weighed & initial weight logged. 3. the various contaminants applied to individual coupons. 4. weight of each coupon taken after contaminant applied.

These coupons would be use for vapor and spray cleaning.

ADDITIONAL COUPONS SUPPLIED BY RELIANCE FOR COMPARATIVE IMMERSION CLEANING TESTING

Reliance also created additional 2024 T3 aluminum coupons to be used for comparative aluminum testing

SAMPLE COUPON PREPARATION

The sample coupons were vapor degreased with AeroTron-AV-5408 and wiped with IPA alcohol prior to application of the contaminate for cleaning to minimize pre-processing contaminate on the surface of the testing coupons.

WEIGHT MEASURES TAKEN AND RECORDED

The following weight measures to a 0.1 grams was taken for each coupon:

1. Weight of coupon before application of contaminate,

2. Weigh of each coupon after application of the contaminate,

3. Weight of each coupon after cleaning in AeroTron-AV-5408

APPLICATION OF THE CONTAMINANT TO THE COUPONS

The contaminate was applied to one side of each part with a lab cotton swab. The side of the part that the contaminate was applied to was marked with an "X" for later reference for your examination of the parts.

REFERENCE PHOTOGRAPHS OF THE COUPONS WITH CONTAMINATE APPLIED

A photograph of each coupon with the contaminate applied was taken.

EQUIPMENT USE FOR THE CLEANING:

Reliance ULTRA 2012LE Vapor, Immersion, Ultrasonic Immersion & Distillate Spray Vapor Degreasing System.

SOLVENT TESTED

AeroTron-AV is manufactured by Reliance and specifically designed to replace n-Propyl Bromide (nPB) & Trichloroethylene (TCE) in vapor degreasing with improved health, safety, regulatory, permitting and environmental benefits. We can assist you every step of the way!

CLEANING PROCESS STEPS IMMERSION CLEANING WITH MULTI-DIP

The parts were immersed for 3 minutes with the part occasionally lifted into the vapor zone and then re-immersed into the solvent.

Step 3 - Clean Coupons

HANDLING AND RACKING OF PARTS

Parts were handled with Nitrile gloves and were in a part rack fixture in a slightly off vertical posture. Each part was cleaned separately.

CLEANING PROCESS STEPS - PROCESS 1: VAPOR WITH SPRAY CLEANING

Each of the coupons was cleaned individually by:

1. Vapor Dwell for 30 seconds, and then

2. Spray with distillate for 30 seconds using the vapor degreaser's hand spray wand

CLEANING PROCESS STEPS - PROCESS 2: IMMERSION CLEANING WITH MULTI-DIP

The parts were immersed for 3 minutes with the part occasionally lifted into the vapor zone and then re-immersed into the solvent.

PACKAGING OF CLEANED PARTS

Cleaned parts were placed in individual sample part bags with the following marked on the bags:

1. AeroTron-AV

2. The specific contaminate

3. the composition of the coupon

4. the cleaning process applied and time frame for each step in the process

Step 3.a - Cleaning Process 1 Steps: Vapor with Spray Cleaning

In the first round of cleaning, each of the 14 coupons was cleaned individually by:

1. Vapor Dwell for 30 seconds, and then

2. Spray with distillate for 30 seconds using the vapor degreaser's hand spray wand

3. Weights of coupons taken after each coupon cleaning to validate no contaminant/residue left on coupon.

Step 3.b - Cleaning Process 2: Immersion Cleaning with Mult-Dip

A second round of cleaning was done on a second set of coupons. Each of the 14 coupons were cleaned individually by:

1. Immersion In AeroTron-AV solvent. The parts were immersed for 3 minutes with the part occasionally lifted into the vapor zone and then re-immersed into the solvent.

2. Again, weights of coupons taken after each coupon cleaning to validate no contaminant/residue left on coupon.

Reliance Goes the Extra Mile:

As the reader may note, this validation study is extensive in that care was to be taken to ensure the coupons were prepared properly (a.k.a no contaminant on coupon prior to cleaning), weighed, contaminant applied, and then removed with 2 different cleaning processes (to assess if vapor and spray is sufficient to remove contaminant or if additional immersion is needed). The parts were weighed again, and carefully bagged. Each bag marked with the results of the cleaning & corresponding weights).

RESULTS & GENERAL OBSERVATIONS

| Contaminant | Results | Weight Change |

|---|---|---|

| 1. Petroleum Jelly Lubricant | Completely Removed | No |

| 2. Extreme Pressure Lubricant #3 | Completely Removed | No |

| 3. MIL-PFR-23827 - Royco 27 Lubricant | Completely Removed | No |

| 4. Boelube 70302-12 Lubricant | Completely Removed | No |

| 5. Boelube 70201-00 Lubricant | Not Tested | No |

| 6. Boelube 70104-04 Lubricant | Completely Removed | No |

| 7. Bondrite L-MR- EA50-PW Aero Lubricant | Mostly Removed | No |

| 8. CRC-3-36 Lubricant | Completely Removed | No |

| 9. Trim Mircosol 590XT Lubricant | Some Residue | No |

| 10. Ultra-Clean Megaflow Hydraulic 32 | Completely Removed | No |

| 11. HC Premium Slideway 220 Lubricant | Completely Removed | No |

| 12. Oil Draw 1429 Lubricant | Completely Removed | No |

| 13. 3M Novec Lubricant | Some Residue | No |

| 14. Titan Lube Lubricant | Completely Removed | No |

The following are comments and observations:

1. All of the parts seemed to cleaned very well from visual observation except the following:

a. Bonderite L-MR-EA50-PW Aero had a "shadow" from both the vapor and spay process steps and also the immersion process steps. This is likely the result of insoluble materials being part of the composition depositing onto the parts.

b. Trim Microsol 590XT ran off of the part as a bead which floated on the surface of the solvent tank. This is consistent with a water based product. It appeared that there was granular material in the solution provided and there seemed to be faint isolated shadows of material on some part of the surface where this contaminate was applied.

c. The 3M Novec Lubricant evaporated as soon as it was applied to the surface of the part, so there was only the possibility of residues upon evaporation being deposited on the parts for cleaning. Where the Novec was applied, no deposit was visually observable before cleaning.

d. Boelube 7010201-00 had turned to a solid before the testing was conducted, so contaminant was not tested.

2. There were no pre-clean/ post clean weight changes for any of the parts.

RECOMMONDATION:

Incorporate Ultrasonic Immersion Into the Cleaning Cycle.

To significantly reduce cycle times, incorporate ultrasonic immersion into the cleaning cycle. Thus reducing the cycle time from 50 minutes to 4 minutes - a 92% reduction in processing time.